Achieving Operational Excellence!

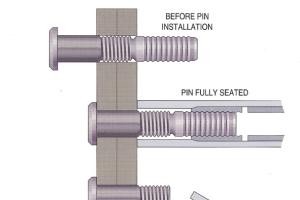

Our organization offers efficient standardization programs that aid in diverse design approaches, parts selection, material specifications, and manufacturing projects…

leading to reduced engineering and manufacturing costs.

Process Re-Engineering

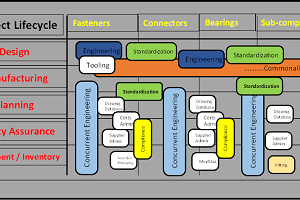

Our Process Re-Engineering solutions enable effective standardization programs that support various design, parts, materials, and manufacturing efforts. This reduces engineering and manufacturing costs and enhances productivity through corporate standardization initiatives. The advantages include decreased unnecessary inventory variety, improved production integrity, and quality control.

Our engineers are dedicated to assisting you, ensuring the clear definition of products and the creation of easily accessible standardization data for your projects.

Standardization Benefits

Standardization and commonality initiatives offer several advantages:

- Quicker learning curves for Design, Manufacturing, and Maintenance

- Decreased paperwork, handling, and storage needs

- more Efficient hardware management, and

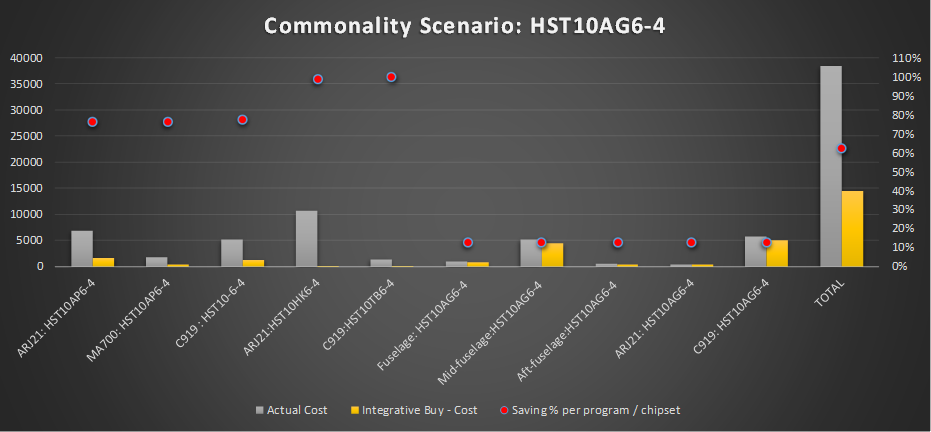

- Cost savings achieved through sourcing commonality initiatives.

Standard Selection Guidelines

Leveraging our practical engineering expertise, we can integrate it into a comprehensive master database that accommodates user-defined selection criteria to assist design, manufacturing, and testing departments. Our platform facilitates the management of intricate BOMs and standard selection criteria providing decision-making support through up-to-date lead time information for high-volume, high-mix requirements.